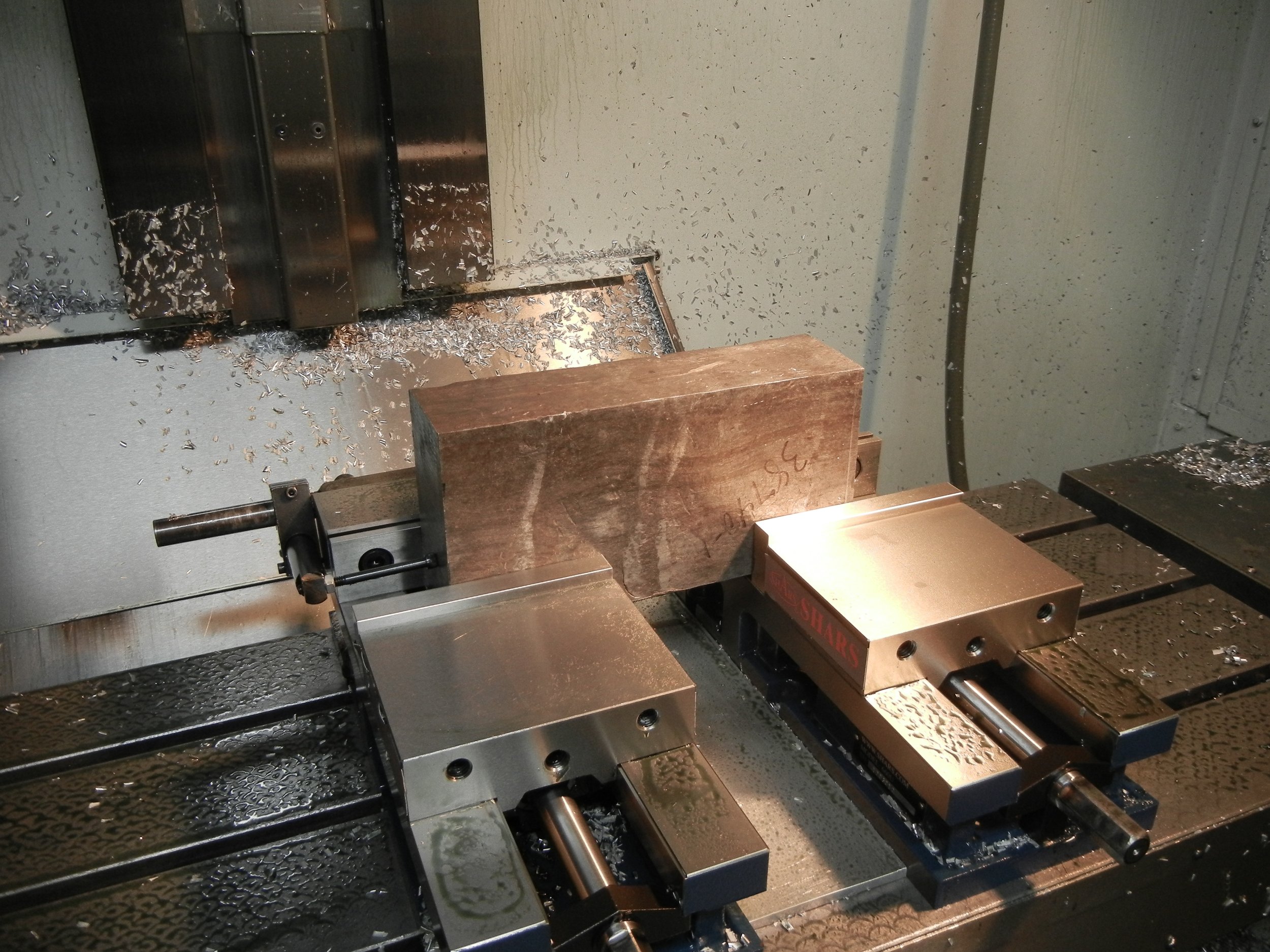

Subtractive Manufacturing

With multiple VMC's, we are able to run multiple operations to guarantee faster leadtime.

Our 4+5 axis is what separates us from most machine shops today, and gives us the edge on the requirements of your parts.

We are also equipped with an additional 4th axis rotary for running simultaneous 4th axis operations for faster lead time.

Glass scales added to our Fadals' table that guarantees accuracy.

Our vacuum plates with hydrophobic filters give us holding solutions for very soft materials such as foam.

Our well maintained Mori Seiki fitted with a Fanuc 21i-T gives us accurate and beautiful finished parts for your needs.

We have a wide assortment of CAT 40 tool holders in many lengths with an extensive library of cutting tools.

Quality Control

With a total of three ROI Optical Omis II in our facility, we have the ability to ensure that your tolerances are met beyond .0001".

Our Retrofitted Cordax CMM will be able to give on the fly measurements that speeds up Leadtime time on parts.

Our Cimcore arm fitted with a Scanworks Laser, we are able to take point cloud data from phyiscal objects and render them digitally with .005" accuracy.

Our Faro Gauge Plus portable measuring arms gives us 7 axis capabilities of measuring your part profiles within .0002"

Additive Manufacturing

Our Raise3D N2 plus has the capability of printing solids 2 feet in height. With materials like Polycast filament, we are able to print items for investment casting that gives us the edge in opportunities compared to most shops.